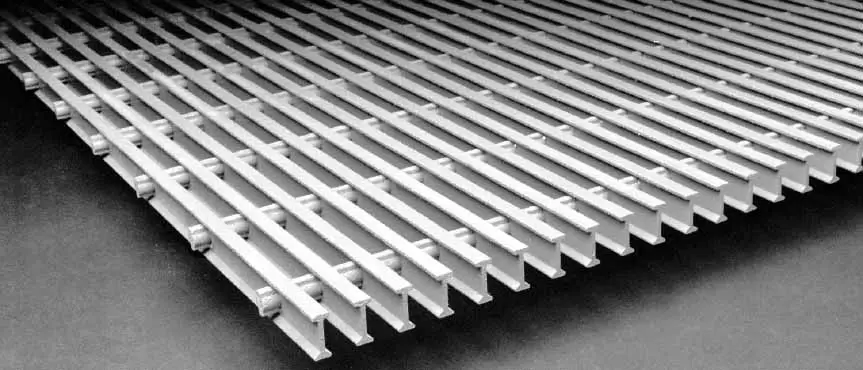

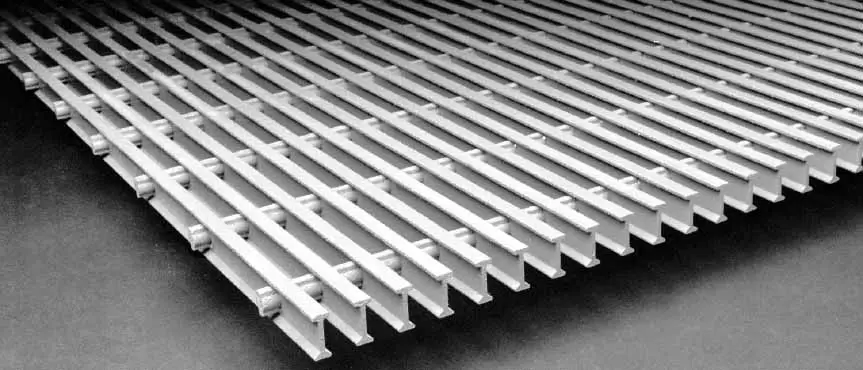

Details

High strength, Fire integrity composite grating for ships. DURAGRID® Phenolic is the “Fit it and Forget it” solution to walkway grating aboard ship. Corrosion- and fire- resistance has made this product a champion in the offshore Oil and Gas industry for over a decade. Features: Strength typically greater than steel grating, No Rust- typically outlasts the ship’s lifespan (can be transferred), Dependable Anti-Skid surface for Safety and Comfort, Lightweight, Easy to install. Regulatory Information: DURAGRID® Phenolic is a USCG Type Approved¹ grating which also has numerous Class Approvals such as ABS, DNV, and LR. For a current list of these approvals, please contact Strongwell directly. For more information on US Coast Guards use of composite grating go to http://www.uscg.mil/hq/cg5/cg5214/. Customers are responsible for consulting the Structural Fire Integrity Matrix and determining their own risk assessment. Typical Ship Applications: Center passage walkway grating, Oil spill tank grating, Winch stand grating, Flying passage (LNG) grating, Manifold grating, Lashing bridge grating, Monkey stage grating, Wheel house stage grating, Gangways - Safe access to bow. Availability** & Panel Sizes: Houston or Factory 3 x 20 ft or 4 x 20 ft, Singapore or Factory 3 x 20 ft or 4 x 20 ft, Rotterdam or Factory 1 x 6 M, Standard panels: 3ft x 20ft, 4ft x 20ft or 1M x 6M. , Standard thickness (height): 1.5” (38 mm), Weight: 3.2 lbs/SF (15.6 kg/M²) **Strongwell can also drop ship to a specific location or port. Performance: 312 PSFU (14.9 kN/m2) uniform loading* (SF [Safety Factor] + 6:1) , 700 PSC (10.2 kN/m) concentrated loading* (SF + 5:1) *Based on a deflection of .25 in or 6 mm Installation: DURAGRID® Phenolic installs the same way steel grating is installed. The bearing bar is the load carrying member which runs between supports. This is the panel length and is typically designated with a (BB) after the dimension to avoid confusion. DURAGRID® Phenolic does not require any banding after cutting. Loads are effectively transferred by a series of cross-rods spaced every 6” (150 mm) (sometimes referred to as “cross-rod pitch”). Installation is easy; the grating can be cut using simple hand tools such as a circular saw (diamond or masonry blades suggested) or a jig saw (carbide grit blades suggested). Panels are lightweight – single panels are typically moved by hand. When ordering, please specify: Square Foot (SF) or Square Meter (M²) Measurements of the areas that needs grating, Hardware (Part # 744 clip & 797 bolt set) – 4 clips per panel or 4 clips per M2