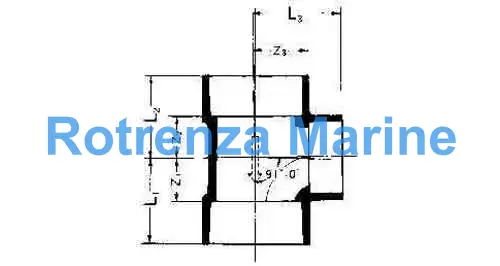

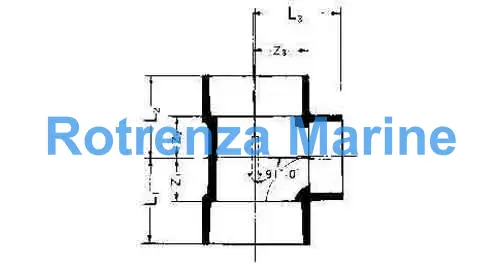

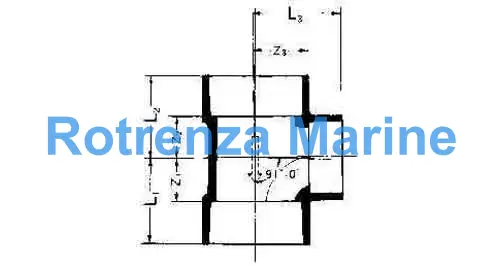

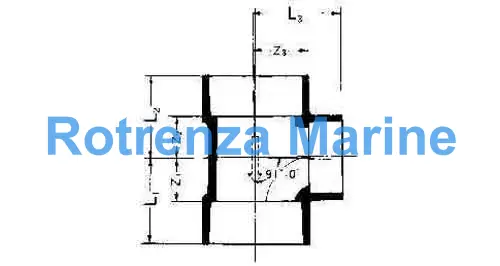

Coupling joints, because of their greater flexibility and economy, are steadily replacing flanged pipe joints in today’s plant and marine applications. Unlike flanged joints, couplings not only eliminate the need for costly welding but also compensate for extreme degrees of pipe linear expansion, vibration, and laying deflection. From chemical plants to mammoth tankers, these couplings are utilized extensively throughout plant and marine piping. As a wide range of models is available, the most common models have been selected and described below. 1. Construction: As illustrated above, the most common models consist of a middle ring (1) two followers (2) two wedge gaskets (3) four bolts & nuts (4) and two stop bolts (5) Both the middle ring and the followers are made of hot rolled steel, and the wedge gaskets are made of natural or synthetic rubber. When the bolts are tightened, the followers press the gaskets against the spherical surface of the pipes and the tapered surface of the middle rings providing a leak-tight connection. When the expansion force of the pipes exceeds the wedging force, the pipes slide and deflect within the gaps between the outer surface of the pipes and the inner surface of the middle ring and followers. 2. Features: The structural design of these flexible pipe couplings offers easy and economical pipe jointing. Pipes can be jointed easily with the use of a spanner. Centering of the pipes and finish-grinding of the pipe sections is not required. Compared with flanged pipe joints, these pipe couplings assure economical pipe jointing without the need for costly welding or any other additional procedures. Usually absorbs 65 – 135 mm of pipe linear expansion (specially available models absorb more than 200 mm of linear expansion) and a considerable degree of pipe vibration as well. Also, they allow for joint deflection up to 6 degrees and can join pipes of different material and/or diameter. 3. How to order: When ordering, please specify the following points. 1. Kind of pipes to be connected (steel, cast iron, vinyl, etc) 2. Pipe outside diameter.....mm 3. Working pressure.....kgf/cm2 4. Kind of liquid or gas of the line content (desired gasket material) 5. Rust preventive treatments (paint) Ductile Cast Iron Middle Ring & Follower: These couplings are mainly used for oil loading pipes, ballast pipes, digester pipes and other conduits on board. These couplings are made of ductile cast iron. Couplings made of cast steel are also available upon request. Couplings of sizes other than those listed above are also available upon request.

Request a Quote

PIPE COUPLING FLEX FOR PLAIN, END PIPE 600MM DUCTILE C.IRON

IMPA CODE: 735030In Stock

- Category:

- Unit of Measure: SET